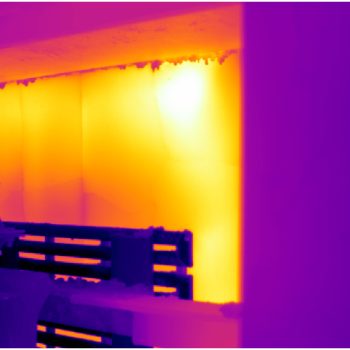

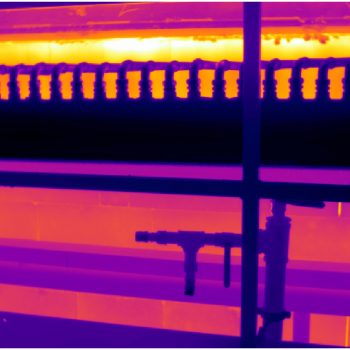

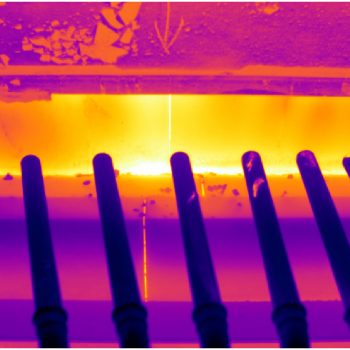

In serious cases these faults or problem areas can be brought to the client’s attention immediately, allowing the necessary remedial action to take place at an early stage, possibly preventing dangerous occurrences and catastrophic failures.

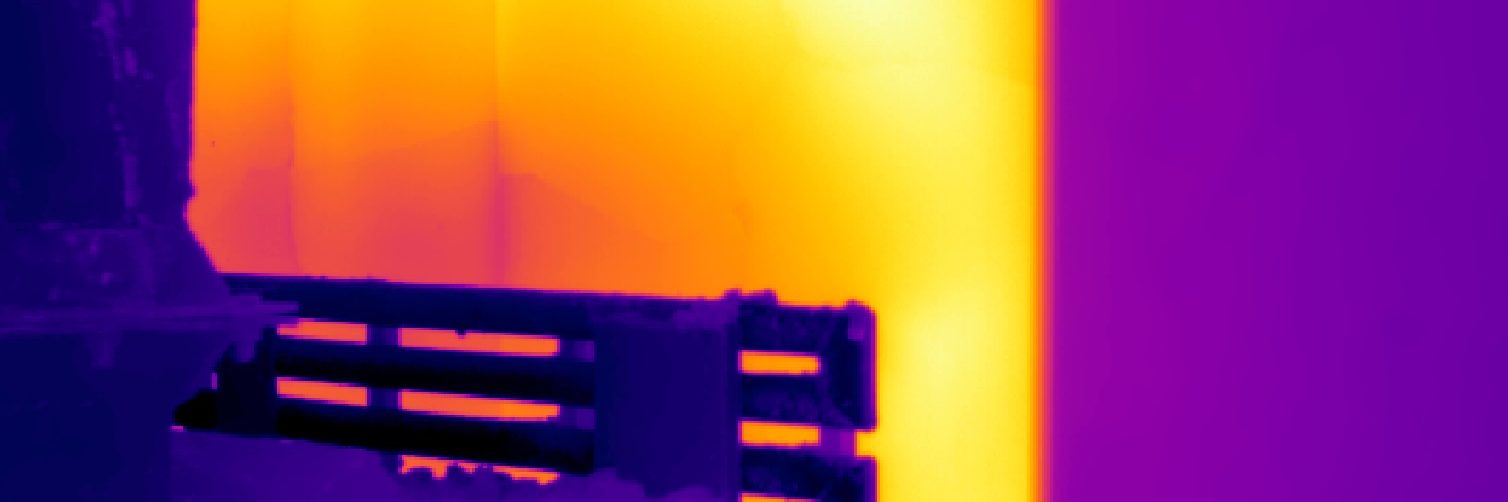

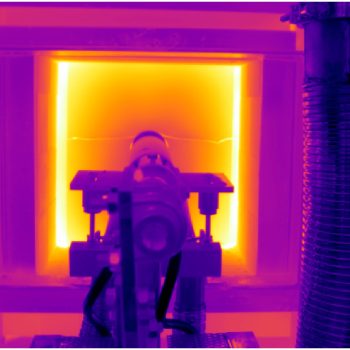

A furnace or kiln thermographic survey or inspection can be completed at any time convenient to the client, and can be incorporated into existing predictive and preventative maintenance programmes and risk avoidance measures.

However, following the commissioning of a new furnace or kiln or following remedial repairs to a running furnace or kiln is an ideal time. Base line measurements can be taken and logged, then referred back to during future surveys or inspections to monitor the furnace condition.

Key points

- Structure and refractories deteriorate once commissioned.

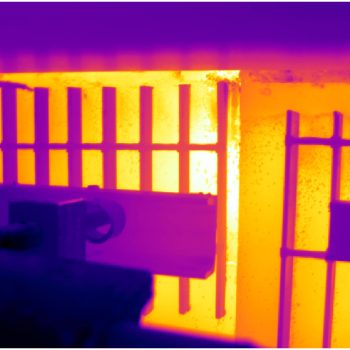

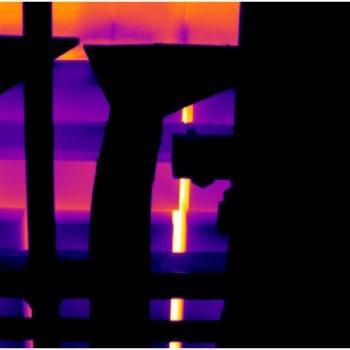

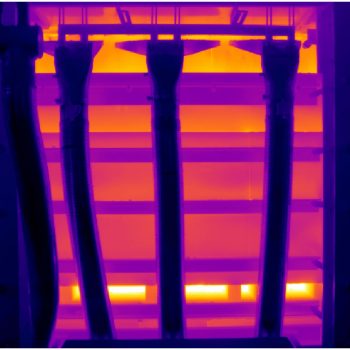

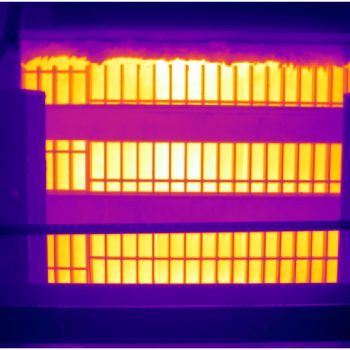

- Wear rates are not always apparent with visual monitoring.

- Wear rates can be more accurately assessed with thermal imaging techniques.

- Data can be collated and monitored, allowing more precise and accurate planning.

- Instant fault or problem area diagnosis.

- Early stage remedial action.

- Reduced risk of dangerous occurrences and catastrophic failure.