This deterioration of mechanical equipment and components is not always apparent or detected by conventional checks such as routine monitoring and maintenance or vibration and oil analysis.

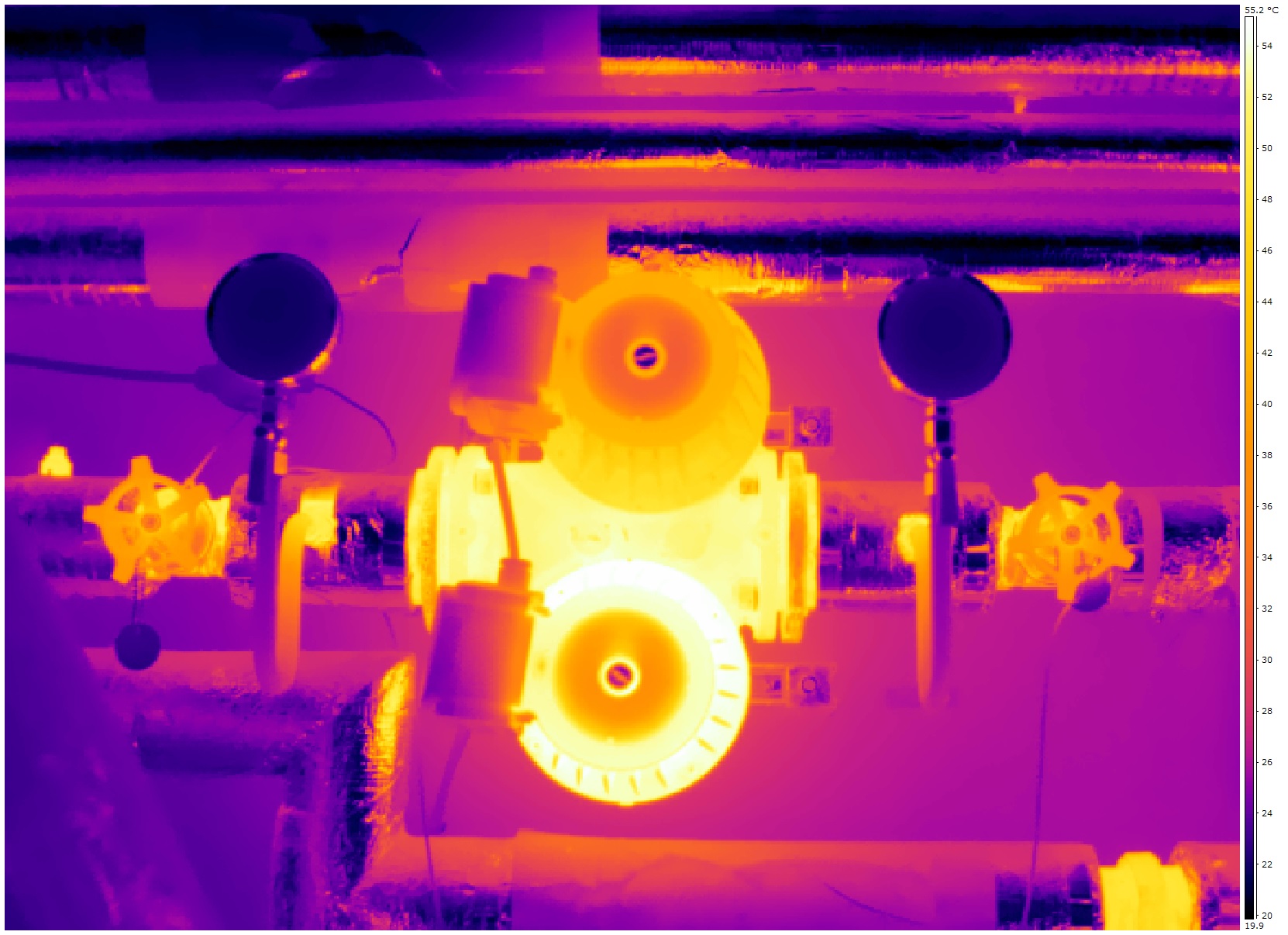

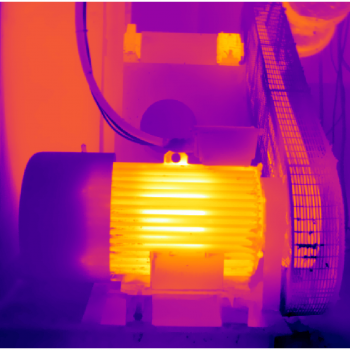

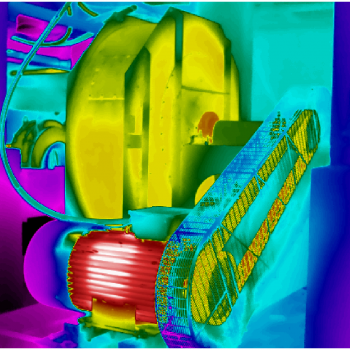

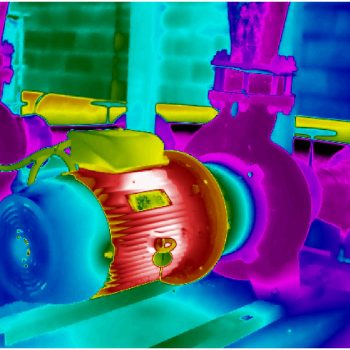

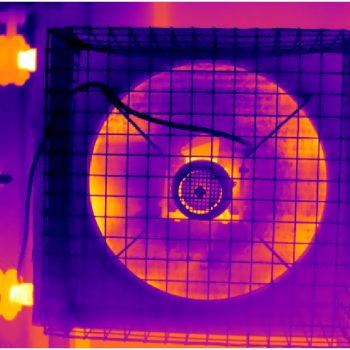

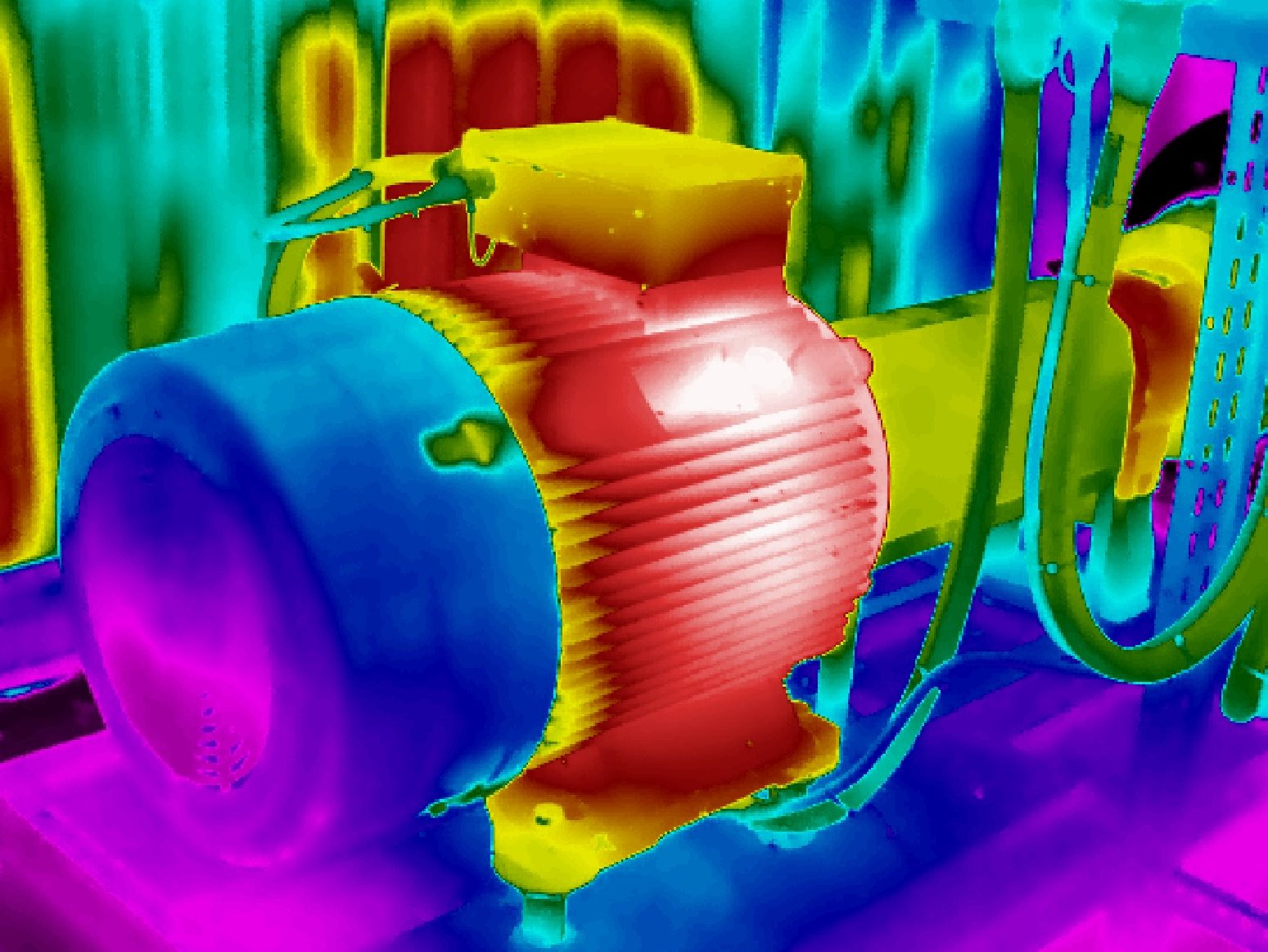

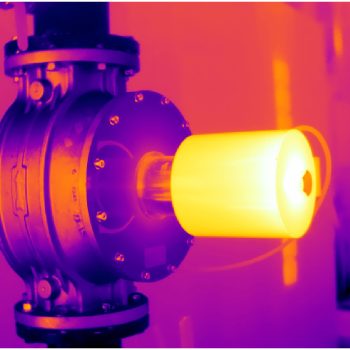

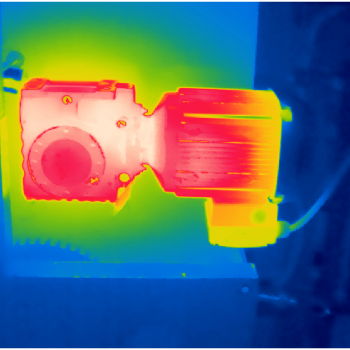

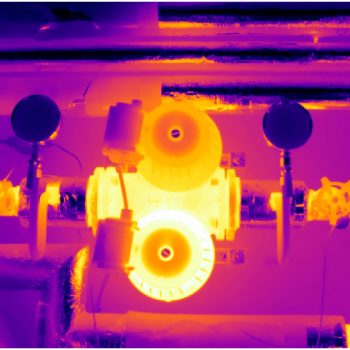

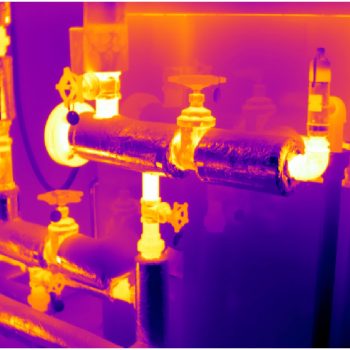

However, when running and under load, these faults can become clearly visible with the aid of thermal imaging techniques.

In many cases this allows for instant fault diagnosis which in serious cases can be brought to the client’s attention immediately, allowing the necessary remedial action to take place at an early stage.

Key points

- Equipment and components deteriorate once commissioned.

- Environmental conditions can increase plant deterioration.

- If uncorrected failure will occur.

- Faults are not always apparent with conventional testing.

- Early stage remedial action.

- Faults can become visible with thermal imaging when energized.

- Instant fault diagnosis.